Introduction

Hydrogen chloride (HCl) plays a vital role in industrial production. While China’s HCl synthesis technology continues to advance and is widely adopted in chemical enterprises, frequent incidents such as furnace explosions remain a concern. These failures not only damage equipment and reduce production efficiency, negatively impacting economic benefits, but also pose severe risks to worker safety, including physical harm and psychological stress. Therefore, studying operational failures and optimizing improvement measures are crucial for ensuring stable furnace operation and workplace safety.

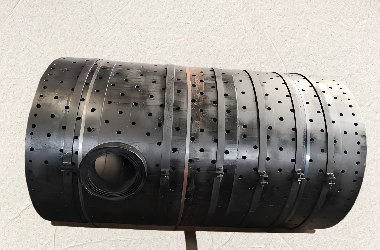

1. Process Overview of HCl Synthesis Furnaces

A company currently operates 24 HCl synthesis furnaces, including:

- 9 TQZ-140 furnaces, each with a processing capacity of 120 tons/day and steam byproduct output of 0 t/h (0.25 MPa pressure).

- 15 SZL-1600 furnaces, each with a processing capacity of 140 tons/day and steam byproduct output of 1 t/h (0.3–0.6 MPa pressure).

All furnaces are constructed from graphite + Q345 steel and equipped with independent falling-film absorption and tail gas absorption systems for producing high-purity hydrochloric acid (>31% concentration).

Process Flow:

- Hydrogen (H₂) from pretreatment undergoes stabilization via buffer tanks and orifice flow meters before entering the furnace.

- Chlorine (Cl₂) is introduced at a 05:1 molar ratio (H₂:Cl₂) for combustion at the burner head, forming HCl gas.

- The gas is cooled in the graphite upper section and transported to the VCM (vinyl chloride monomer) unit.

- During startup/shutdown or HCl gas diversion, the gas is absorbed into water to form hydrochloric acid, which flows into storage tanks.

- Safety interlocks halt feedstock supply during abnormal conditions.

- Cooling water, pressurized by high-pressure pumps, absorbs heat and circulates back or evaporates in steam drums.

2. Operational Failures and Improvement Measures

2.1 Graphite Block Clogging

Failure:

Prolonged operation leads to pH reduction in the cooling water jacket, causing turbidity, reddish discoloration, and sludge accumulation. This impedes heat exchange, damages graphite blocks, and disrupts production.

Solution:

- Monitor water pH every 3 days and replace if acidic.

- Add flanged cleaning ports at the furnace base for sludge removal.

2.2 Sight Glass Fouling

Failure:

Trace acidic contaminants in Cl₂ and NaOH in H₂ react to form deposits on sight glasses, obstructing visibility and risking control failures.

Solution:

- Install automatic cleaning devices near sight glasses.

- Monitor DCS (Distributed Control System) for pressure fluctuations.

2.3 Hydrogen Pipe Corrosion

Failure:

Carbon steel H₂ pipes corrode at welds due to HCl acid mist condensation, leading to leaks and explosion hazards.

Solution:

- Replace with rubber-lined pipes and use modular flanged joints to simplify maintenance.

2.4 Frequent Baseplate Damage

Failure:

Sediment buildup in cooling water blocks channels, causing overheating and graphite damage. Baseplates require replacement every 3–4 months.

Solution:

- Redesign water inlets to angled entry to reduce sediment accumulation.

3. Maintenance Strategies

3.1 Routine Maintenance

- Daily: Purge steel jackets to prevent sludge buildup.

- Biweekly: Check cooling water salinity to avoid graphite overheating.

3.2 Critical Components

- O-rings (15 mm): Replace periodically due to thermal degradation.

- H₂ pipes and hoses: Upgrade to corrosion-resistant materials.

- Gaskets (sight glasses, furnace mouth, explosion-proof membranes): Replace PTFE gaskets prone to elasticity loss.

- Explosion-proof membranes: Prevent corrosion-induced opacity.

- Rubber seals (Φ1800 baseplate, DN25 condensate drains): Prevent acid/steam leaks.

3.3 Overhaul Procedures

- Inspection: Identify leaks beforedraining cooling water.

- Disassembly:

- Remove bolts, graphite blocks, and steel jackets sequentially.

- Pressure-test components at 200 kPa for 30 min.

- Repair: Seal micro-leaks with phenolic resin; replace severely damaged parts.

- Reassembly: Ensure airtightness via 130–150°C thermal curing.

Conclusion

Proactive maintenance and targeted design modifications significantly enhance HCl synthesis furnace reliability, minimizing downtime and safety risks. Implementing online monitoring and corrosion-resistant materials is recommended for long-term operational stability.