Installation and Operation Manual for Graphite Heat Exchanger

Product User Manual

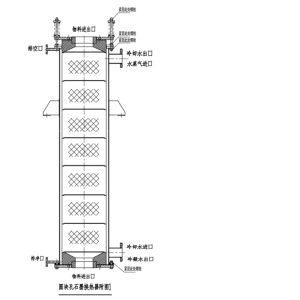

1、 Equipment structure, technical performance, and scope of use

This device is mainly composed of a metal shell and impermeable circular graphite heat exchange blocks.

The longitudinal holes flow corrosive materials, while the transverse holes flow cold and hot carriers (such as water vapor, water, neutral frozen salt water, etc.).

The heat exchange body is assembled in a modular manner, making it easy to disassemble and replace any component.

This equipment is characterized by high structural strength, high temperature resistance, strong pressure resistance, good impact resistance, small size, simple maintenance, etc. It has become an advanced graphite heat exchanger with better performance.

Can be used for evaporation, heating, cooling, condensation, etc.

When using a condenser, a gas-liquid separator needs to be installed at the bottom.

Technical features:

Design temperature: Tube side: 165 ℃

Shell process: 60 ℃

Design pressure: Pipe side: 0.4MPa

Shell side: 0.4MPa

2、 Installation precautions:

In addition to following the general regulations for installation and construction, the installation of this equipment should also pay attention to the following matters:

- It is easy for equipment bolts to loosen during transportation and movement. Please carefully inspect and adjust the bolts before installation.

After the equipment arrives at the factory, all equipment bolts must be tightened to avoid seal leakage.

The tightening bolts should be evenly stressed to avoid damaging the graphite components.

Refer to Figure 1.

- Graphite material is a brittle material.

During the lifting process, the equipment should be lifted and placed gently, and should not be impacted or vibrated to avoid damage. It should not be touched or dragged on the ground, and exposed graphite bodies are strictly prohibited from being pried or tied with steel wire ropes.

- The flange connecting the equipment shall not be used as a lifting or force bearing point, and shall not be subjected to significant torsional stress.

When the external connection is heavy, a separate pipe support should be erected near the heat exchanger.

Especially the top pipeline should not be too heavy, and there should be room for thermal expansion and contraction.

- When taking over connections outside of the equipment, forced installation is not allowed.

The tightening bolts should be evenly and symmetrically operated to avoid damaging the graphite components. The graphite interface sealing gasket should be placed on the graphite surface and not on the steel flange.

And the graphite pipe mouth gasket should not use hard gaskets such as hard polytetrafluoroethylene, but should use soft gaskets such as rubber, expanded PTFE, pure flexible graphite, etc., to facilitate sealing and not damage the equipment pipe mouth.

Refer to Figure 2.

- This device should be installed vertically.

The verticality after installation shall not exceed 2% of the total height.

- If the material contains mechanical impurities, a filter should be installed before the inlet pipe to prevent scaling and blockage of the longitudinal and transverse holes, which may affect the heat transfer effect.

- The pipeline connected to the graphite pipe should be equipped with a stress compensation device.

- The highest (lowest) part of the shell is equipped with an exhaust (clean) pipe, and a valve should be installed during installation. When connecting the exhaust (clean) pipe, blind plates should not be used for sealing.

- When welding and cutting on the shell, do not damage the graphite parts inside.

When welding the support, circulating cooling water should be introduced into the shell to avoid excessive deformation that may prevent disassembly.

When welding is required on the equipment casing, the shell side must be filled with cooling water to the specified position before proceeding.

- When fastening bolts with flat threaded holes (i.e. threaded holes) at the connection between the upper and lower cover plates and the upper and lower heads, they must not touch the graphite upper and lower heads.

Refer to Figure 3.

- During the process of equipment hoisting and installation, each unit must be operated one by one, and it is not allowed to use two or more units at once, in order to avoid damage caused by equipment collision.

3、 Precautions for use:

- It must operate within the technical specifications of this device and is prohibited to use it under excessive temperature and pressure.

The working medium must be suitable for impregnating graphite with modified resin.

When the pressure of the conveyed medium exceeds the design pressure of the equipment, a pressure reducing device should be installed at the inlet pipe of the medium.

- To avoid strong impact of materials, gradually adjust the flow rate to the maximum when opening and closing the valve.

- Before starting to use the equipment, the vent valve at the top of the shell should be opened and closed only after the air inside the shell is completely expelled.

- When using a heater, the material should be introduced first, followed by the heat carrier.

When the heat carrier is introduced, its flow rate should be small to large, and the temperature should be low to high, slowly introduced to ensure uniform heating of the equipment. Overtemperature and overpressure are not allowed to avoid large temperature differences and sudden changes, which may cause equipment damage.

Avoid equipment damage caused by dry burning.

When parking, the order is reversed.

- When condensing or cooling, first introduce the coolant and then the material.

When using frozen saltwater, first pass the heat medium and then the frozen saltwater.

When parking, the order is reversed.

If there is steam or non condensable gas inside the shell (which may reduce the heat transfer efficiency), it should be discharged.

- When the equipment is stopped from use, the residual cold and hot carriers inside should be drained.

And thoroughly remove it by blowing or other methods.

Especially in winter.

And take appropriate insulation and antifreeze measures.

At the same time, all bolts of the equipment need to be re tightened before and after starting and stopping to ensure a leak free seal.

- For materials that are prone to crystallization and scaling, the materials should be drained when parking. After parking, the longitudinal holes should be rinsed from top to bottom with an immersion solution (such as hot water) that can dissolve the crystals (or precipitates) and does not damage the graphite parts.

There should be no large solid particles in the longitudinal and transverse channels to avoid wear on the graphite material.

- It is strictly prohibited to suddenly raise or lower the temperature to avoid damage to the equipment.

- The equipment should not be left unused for a long time to prevent cracking and damage.

If it needs to be placed, the longitudinal and transverse holes should be filled with water and regularly checked for lack of liquid. If there is a lack of liquid, it should be filled up and effective anti freezing measures should be taken in winter.

- During use, non condensable gases at the top of the shell and condensed water at the bottom must be frequently discharged.

- Regularly check whether the cooling medium of the equipment is interrupted.

- Minimize the number of times the equipment is turned on and off as much as possible to extend its service life.

All equipment bolts must be re tightened before driving after each parking.

To ensure that the sealing gasket is leak free.

The tightening bolts should be evenly stressed to avoid damaging the graphite components.

- When gasket leakage is found during use, the operation should be stopped to avoid equipment damage.

The fastening bolts should be readjusted.

If there is still leakage after adjustment, all materials in the shell side should be eliminated and the gasket should be replaced again.

5、 Maintenance precautions:

- When the heat transfer capacity decreases too much and the overall flushing effect is not significant or leakage is found, the equipment needs to be disassembled for inspection.

Before dismantling and inspection, it is necessary to rinse with hot water to remove residual corrosive media.

Disassembly and inspection should be carried out in a vertical position.

- Regularly check whether the water and gas discharged from the shell contain materials in the longitudinal holes.

If there is any, the vehicle should be stopped immediately for inspection to avoid corrosion of metal components.

- Please maintain good cooling water quality to avoid equipment damage caused by poor heat exchange.

- The equipment should be regularly cleaned to remove scale and improve heat transfer capacity.

Avoid internal stress concentration and equipment damage caused by poor heat transfer.

When cleaning, it is strictly prohibited to use mechanical methods, and steam blowing or chemical methods should be used.

When using chemical methods for descaling, the chemical raw materials used should ensure that they do not react with graphite materials and adhesive.

- When repairing equipment, it is strictly prohibited to knock, bump or damage the bonding joints between graphite parts and adhesive.

- When repairing equipment steel parts using electrical welding or other methods, effective cooling and protective measures should be taken to prevent damage to graphite parts and adhesive joints.

- Users should regularly perform anti-corrosion treatment on the outer surface of the equipment based on the raw materials, media, and environmental conditions used.

- When equipment components are damaged, please contact our company promptly for repair.