Methods to Extend the Service Life of Quartz Tubes in Hydrochloric Acid Synthesis Furnaces

Background

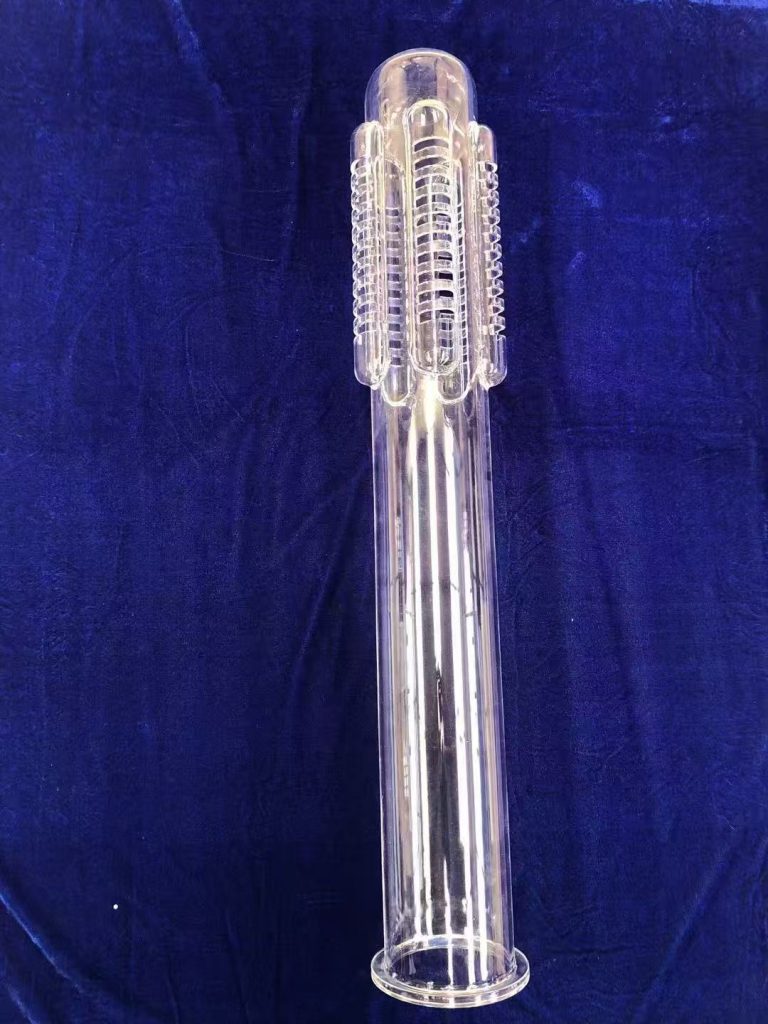

With continuous improvements in hydrochloric acid production processes and increasing market demands for high-quality hydrochloric acid – particularly the need for high-purity hydrochloric acid in ion-exchange membrane alkali production – the energy-efficient “three-in-one” furnace method for producing high-purity hydrochloric acid has gained widespread adoption. However, the quartz tubes, as key components of three-in-one furnaces, have relatively short service lives, and their frequent damage poses a significant challenge.

Quartz tube failures lead to shutdowns of hydrochloric acid production systems, directly affecting production output and causing fluctuations throughout the chlorine gas system. This places additional burdens on other chlorine-using units, complicates chlorine balance maintenance, and negatively impacts production efficiency and chlorine recovery rates. Moreover, as quartz tubes are expensive components, frequent replacements increase maintenance costs and production expenses, ultimately reducing profitability. Therefore, proper use of quartz tubes to extend their service life is an urgent issue that needs addressing.

Based on years of practical experience with three-in-one furnaces, this article analyzes the main causes of quartz tube damage and proposes corresponding preventive measures to extend their service life.

1. Damage Caused by Impurities in Hydrogen Gas

When hydrogen gas treatment is inadequate, it can carry significant amounts of moisture. The water vapor in hydrogen gas readily condenses into droplets, resulting in excessive water content. When these droplets are carried into the three-in-one furnace and splash onto the extremely hot quartz tubes (which reach temperatures above 2000°C), the quartz tubes can crack or shatter.

The water in hydrogen gas contains trace amounts of inorganic salts (primarily sodium chloride, sodium hydroxide, sodium carbonate, and sodium bicarbonate). When these salt-laden water droplets splash onto quartz tubes, the water evaporates, leaving salt deposits on the tube walls. As these deposits accumulate, they can damage the quartz tubes due to differences in thermal expansion coefficients between the salts and quartz glass. Additionally, salt buildup can clog the tubes, disrupting gas (flame) flow and causing flame flare-ups. In severe cases, this can overheat and deform the furnace’s graphite components, leading to quartz tube detachment or crushing.

Furthermore, at high temperatures, salt deposits corrode quartz tubes, forming white ceramic-like substances that flake off in layers, further shortening tube lifespan.

Solutions:

- Enhance hydrogen gas cooling and drying:

- Increase cooling water spray volume in hydrogen scrubbers to remove salts

- Improve cooling after hydrogen compression:

- Increase heat exchange area in hydrogen separator coolers

- Increase cooling water flow rate

- Lower cooling water temperature

- Use chilled water from absorption chillers (e.g., lithium bromide units) in summer

- Install hydrogen buffer tanks at pipeline high points with water collection devices

- Regularly remove salt deposits:

- Determine cleaning frequency based on scaling rate

- For severe scaling, first flush with 30% hydrochloric acid, then rinse with water

2. Impact of Chlorine Gas Impurities

After chlorine gas treatment, poor mist elimination can leave excessive acid mist in the gas. This is particularly severe when using tail gas from liquid chlorine production as feedstock, as the liquefaction process causes fine acid droplets to coalesce into larger ones.

These acid mists react with iron in pipelines, forming viscous pastes (mainly iron sulfate, ferric sulfate, and sulfuric acid). When these substances enter quartz tubes, they sinter into salt deposits similar to those from hydrogen impurities, damaging the tubes.

Solutions:

- Additional purification before chlorine enters the furnace:

- Install mist eliminators

- Regularly discharge accumulated impurities

- Cost-effective solution: Add silicone oil-glass wool mist eliminators to existing chlorine buffer tanks

3. Damage During Furnace Start-up/Shutdown

Start-up Issues:

- Moisture on tubes from prolonged downtime or improper cleaning can cause cracking during ignition

- Rapid loading after ignition can thermally shock tubes

Shutdown Issues:

- Immediate hydrogen line disconnection while system is still hot can cause thermal shock

Preventive Measures:

- Before start-up:

- Remove and thoroughly dry all quartz tubes

- During start-up:

- Gradually increase load over 1 hour

- During shutdown:

- Allow furnace to cool completely before depressurizing

- Pay special attention in winter conditions

4. Installation-Related Damage

Improper installation can damage quartz tubes due to:

- Mismatch between tubes and furnace

- Incorrect clearance between quartz tubes and graphite seats:

- Too small: Thermal expansion crushes tubes

- Too large: Tubes may detach and break

- Misalignment causing uneven heating

Proper Installation:

- Use furnace-matched quartz tubes

- Ensure secure, vibration-free installation

- Maintain uniform clearance around tubes

5. Operational Abnormalities

System explosions or excessive vibrations can damage quartz tubes. The hydrochloric acid production system operates under hydrogen-rich negative pressure, making it vulnerable to:

- Air ingress forming explosive mixtures

- Chlorine excess forming explosive chlorine-hydrogen mixtures

Prevention:

- Maintain proper Cl₂:H₂ ratio (1.00:1.05-1.10)

- Ensure system airtightness (oxygen <4% in tail gas)

- Install rupture discs at critical locations

- Control gas purity:

- Hydrogen ≥98%

- Chlorine hydrogen content ≤3%

- Special care when using tail chlorine

6. Manufacturing Defects

Quartz tube quality issues include:

- Uneven flanges causing installation problems

- Non-uniform wall thickness leading to stress concentrations

Solution: Strict quality control in tube selection

Implementation Results

These measures significantly reduce quartz tube failures, extending service life while lowering maintenance costs and improving system stability.

efhiuxnoin