Graphite anti-corrosion equipment accessories

Graphite heat exchanger, hydrochloric acid synthesis furnace, graphite condenser components

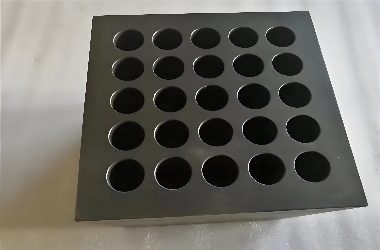

Graphite heat exchange block

Graphite block heat exchangers are mainly used for heat exchange in corrosive media such as hydrochloric acid, sulfuric acid, acetic acid, and phosphoric acid.

We can provide customized processing services for integral graphite heat exchangers and corresponding graphite heat exchange blocks and other accessories.

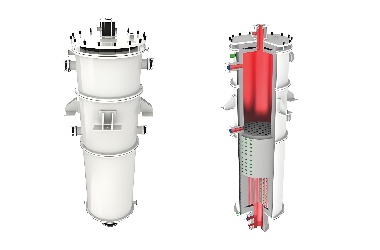

Graphite hydrochloric acid synthesis furnace and accessories

Graphite synthesis furnace, also known as hydrogen chlorine synthesis furnace, HCl combustion furnace, hydrogen chlorine gas combustion furnace,Provide synthesis furnace accessories and maintenance services.

Size:DN300-DN1600

Function: 2-in-1 hydrochloric acid synthesis furnace, three in one hydrogen chloride synthesis

Feature: by-product steam

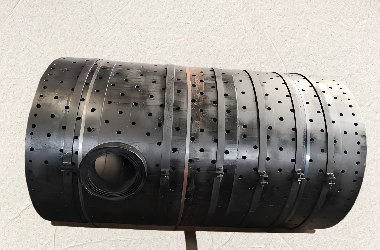

Graphite Tower

The graphite rapid cooling tower uses fine particle graphite as the core component. The flue gas temperature can reach over 1100 ℃ for ultra-high temperature impact. It can be used for flue gas rapid cooling, chemical distillation, evaporation concentration and other purposes.

Graphite bowl, graphite box

The graphite box bowl is made of special high-purity, high-strength, and high-density graphite material; After CNC machining, graphite products such as graphite ark, graphite box bowl, graphite crucible, graphite casting crucible, graphite oil tank, pulling tube, pulling plate, pulling rod mold, etc.

Process customized graphite according to the drawings

Process and manufacture according to the graphite grade material provided by the customer and the drawings provided by the customer. We use CNC machining technology and provide special impregnated graphite components with processing techniques such as impregnated phenolic resin and asphalt.