PTFE pipe anti-corrosion lining

PTFE/PFA anti-corrosion technology is a commonly used chemical production solution for fluids containing corrosive media such as acids. With the chemical inertness, high temperature resistance, and different production process schemes of PTFE or PFA lining, it can cope with the harsh chemical production characteristics. We provide various production solutions such as roller lining, plate lining, and molding to meet different requirements for pipeline anti-corrosion technology.

PTFE pipe or PFA pipe

Tetrafluorofluorofluoroethylene pipe (Polytetrafluoroethylene pipe/PTFE pipe) is a high-performance plastic pipe material for industrial use, made of polymerization of tetrafluoroethylene monomers, and is mainly used to transport highly corrosive gas-liquid media in chemical equipment, aerospace and other fields.

Dimensions:DN15-DN1000

PTFE material :PTFE/PFA/F40

Technique:rolling lining, spraying, plate lining, and molding lining,

PTFE lined pipe expansion joint

PTFE pipeline expansion joint is mainly used to compensate for the displacement of the pipeline due to temperature changes, mechanical vibration or installation errors, so as to reduce the risk of system stress concentration and equipment damage.

1、Four types of ripple specifications: FB, FX, FGF, FXD, FXZF

2、The working temperature is -50~150 ℃. When it exceeds 150 ℃, it shall be resolved through agreement between the supply and demand parties

1、Nominal working pressure (MPa): -0.01, -0.05, 0.01, 0.05, 0.1, 0.25, 0.6, 1;

2、Nominal size:DN25-DN6000

PTFE pipe /PFA pipe Three way pipes and elbows

The PTFE pipeline tee elbow is a pipeline accessory that combines tee and elbow functions, mainly used in industrial pipeline systems to meet the dual requirements of medium diversion and direction change. Its core functions include:Diversion and turning

The working temperature is -50~150 ℃. When it exceeds 150 ℃, it shall be resolved through agreement between the supply and demand parties

elbow pipe: DN25-DN300,center height:98-315mm

three-way pipe:

DN25-DN300,center height:98-300mm,length:196-600mm

PTFE lined corrugated winding pipe

The product is used for chemical pipeline connection, tanker discharge pipe, displacement compensation and vibration elimination. It can be used as a tubular reactor or heat exchanger in special scenarios

The working temperature is -50~150 ℃. When it exceeds 150 ℃, it shall be resolved through agreement between the supply and demand parties

The diameter is DN10-150mm, the length can reach 20-2000mm, and the standard range of wall thickness is 1.5mm to 2.2mm,

Molded PTFE tube sheet

Molded PTFE heat exchanger tube sheets are used for non-metallic heat exchangers, such as silicon carbide tube heat exchangers, PPS heat exchanger tubes, graphite tube heat exchangers, etc

It can be used for a long time in the temperature range of -200℃ to +260℃, and can withstand corrosion of almost all chemical media, including strong acids, strong alkalis and organic solvents.

DN100-DN2000

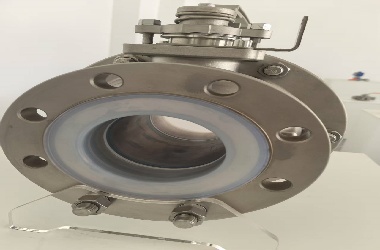

Molded PTFE valve/PFA valve

PTFE molded valves (also known as fluorine lined valves) achieve sealing control of highly corrosive media by compounding polytetrafluoroethylene (PTFE) material on the inner or outer surface of the metal substrate. It can resist corrosive media such as strong acids, strong alkalis, and organic solvents, and is suitable for controlling corrosive fluids in industries such as chemical, pharmaceutical, and food.

1. By using an elastic lip seal seat and a herringbone PTFE packing structure, zero leakage sealing is achieved, with a working temperature range of -196 ℃ to 250 ℃.

2. Using pneumatic actuators, it can achieve fast opening and closing, compact structure, and support remote control, suitable for automated production scenarios.

PTFE valve types: butterfly valve, ball valve, discharge valve, globe valve, diaphragm valve, check valve

PTFE valve control types: manual, electric, compressed air control