PTFE anti-corrosion lining

PTFE/PFA anti-corrosion technology is a commonly used chemical production solution for fluids containing corrosive media such as acids. With the chemical inertness, high temperature resistance, and different production process schemes of PTFE or PFA lining, it can cope with the harsh chemical production characteristics. We provide various production solutions such as roller lining, plate lining, and molding to meet different requirements for pipeline anti-corrosion technology.

PTFE/PFA pipeline

PTFE/PFA expansion joint

The product features include multi-dimensional compensation capability, noise reduction and vibration isolation, no reverse thrust design, and excellent sealing performance, which can adapt to high temperature and corrosive media environments. Provide a specification range of DN25-6000mm, with pressure ratings ranging from PN0.6 to 4.0MPa

PTFE/PFA Three way pipes and elbows

Molded PTFE tube sheet

Tailored tube plate components for pressureless sintered silicon carbide tube heat exchangers and special corrosion-resistant graphite material heat exchangers, featuring corrosion resistance, high temperature resistance, and negative pressure resistance

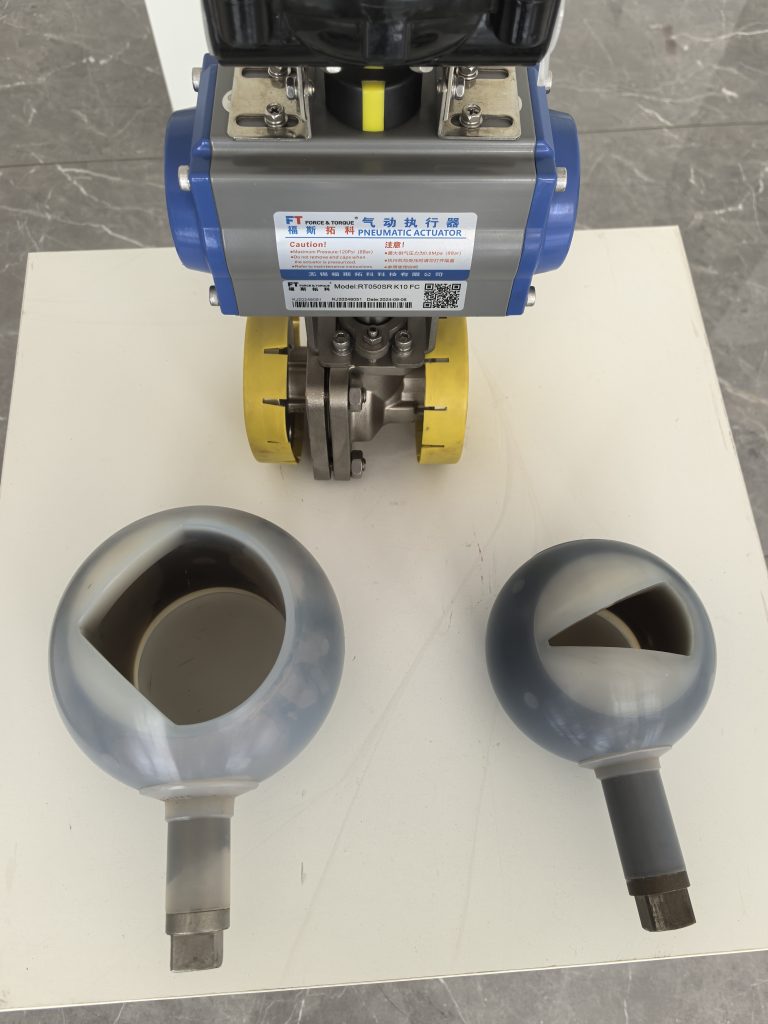

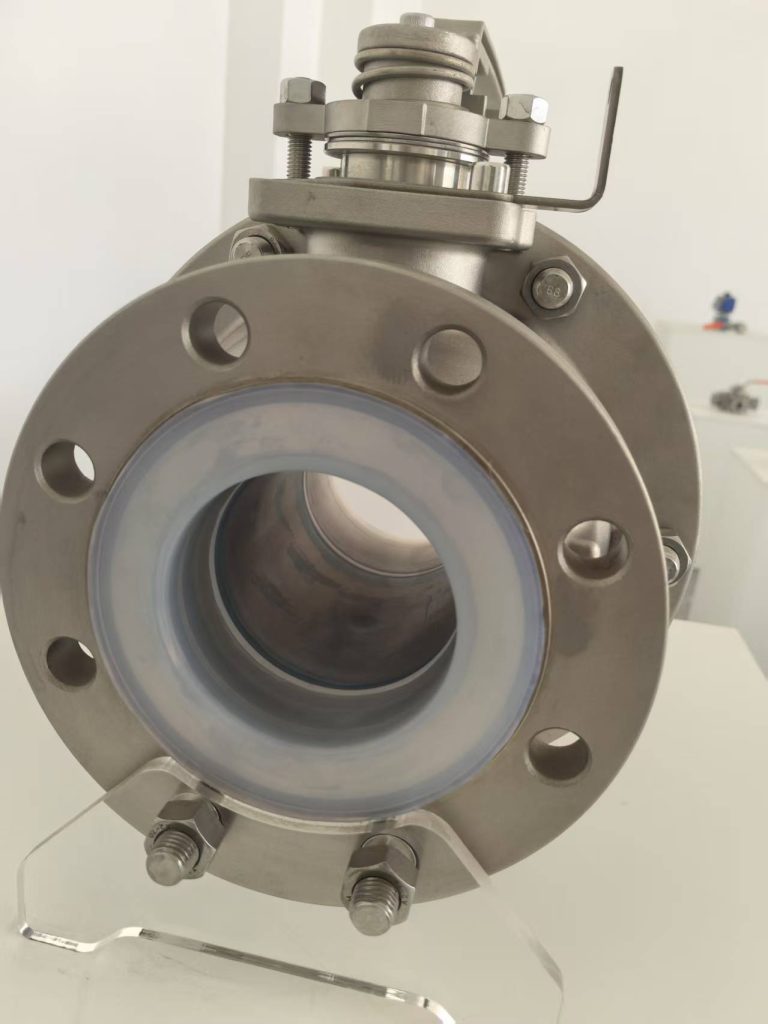

Molded PTFE/PFA valve